Good materials make great interiors. If furniture is the body, plywood is often the skeleton — choose it well and the piece will stand strong for decades. This guide explains how plywood is made, what types exist, practical on-site checks, and modern engineered alternatives like HDF and HDHMR.

Quick Primer — How Plywood is Made

Plywood is not one single sheet of wood, but a careful construction:

Logs are peeled into thin veneers.

Veneers are dried, sorted, and layered with adhesive.

Each layer is placed with alternating grain directions (cross-graining) to reduce warping.

The stack is cold-pressed, then hot-pressed under heat and pressure.

Sheets are trimmed, sanded, and graded.

This process creates panels that are stronger, more dimensionally stable, and more resistant to moisture than solid wood alone.

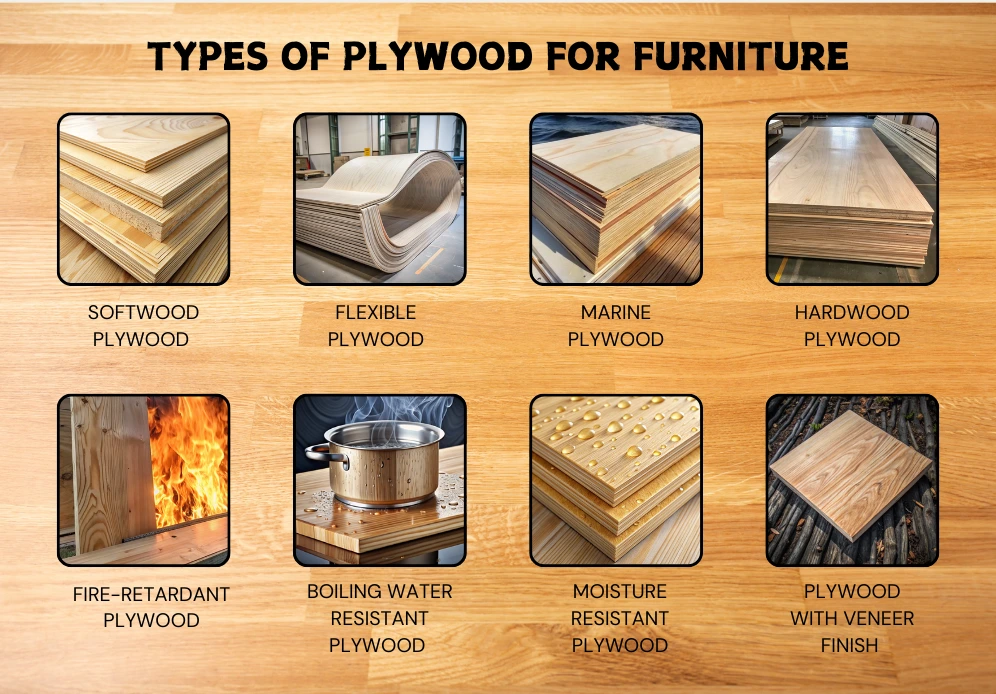

1. Types of Plywood for Furniture

Here’s a breakdown of the most relevant plywood types you’ll encounter while designing or furnishing a modern home:

Commercial Plywood (Alternate Core):

Also called “MR grade commercial ply.” It typically uses alternate hardwood and softwood cores. More affordable than premium hardwood-core ply, but strong enough for wardrobes, TV units, and furniture in dry zones.Moisture-Resistant (MR) Plywood:

Made with urea-formaldehyde resin, MR is suitable for areas with mild humidity like bedrooms and living rooms. It resists moisture but is not waterproof.Boiling Water-Resistant (BWR) Plywood:

Bonded with phenol-formaldehyde resin, BWR withstands kitchen steam and light water contact. Ideal for kitchen cabinets and semi-moisture areas.Boiling Water-Proof (BWP / Marine) Plywood:

The most robust grade, manufactured as per IS 710. Highly durable, fully waterproof, and suitable for bathrooms, sink units, and even outdoor furniture.Hardwood Plywood:

Uses hardwood veneers (e.g., Gurjan, Eucalyptus) in its core, giving it strength, density, and excellent screw-holding capacity. Perfect for structural furniture like beds and heavy wardrobes.Softwood Plywood:

Made from woods like pine or fir. It is lighter, easier to work with, and often more affordable, but less dense than hardwood. Best for decorative, lightweight furniture.Flexible Plywood (Bendable Ply):

Specially manufactured with thin veneers that can bend without breaking. Used for curved furniture designs, archways, or creative wall panels.Fire-Retardant Plywood:

Chemically treated to resist ignition and slow flame spread. Common in commercial interiors, high-rise apartments, or safety-sensitive areas like kitchens.Veneer-Finished Plywood:

Standard plywood faced with a thin decorative veneer layer (teak, oak, walnut, etc.). Combines the strength of plywood with the beauty of natural wood finishes.Red-Core Plywood:

Specially treated to resist termites and warping, with a distinctive reddish hue. Good for kitchens and coastal regions where durability is vital.

👉 Design Tip: Always match plywood type with location. Bedrooms can use MR or commercial ply, kitchens should lean toward BWR or BWP, and creative curves come alive with flexible plywood.

2. Thickness & Core — Match Function to Build

6–9 mm: Back panels, drawer bottoms.

12 mm: Lightweight doors, mid-load shelves.

18 mm: Standard for cabinets, wardrobes, beds.

25 mm: Heavy load-bearing countertops, tabletops.

For longevity, prefer hardwood cores (dense, termite-resistant) over alternate or recycled cores.

3. How a Common Person Can Check Plywood Quality On-Site

Stamp & Label: Look for ISI marks (IS 303, IS 710).

Edge Check: Run your finger on the side — voids or air gaps mean weak ply.

Glue Line: Dark, uniform glue lines suggest phenolic resin (BWR/BWP).

Weight Test: Heavier boards are usually denser and stronger.

Screw Test: Drive a screw into a sample — good ply grips firmly.

Water Spot Test: Place a drop of water on the edge. Quick swelling = poor quality.

4. Engineered Alternatives — MDF, HDF & HDHMR

MDF (Medium Density Fibreboard): Smooth surface, great for painted finishes; avoid in wet areas.

HDF (High Density Fibreboard): Denser and stronger than MDF, used for flooring bases and furniture backings.

HDHMR (High-Density, High-Moisture-Resistant Board): Next-gen MDF variant treated for moisture resistance. Popular for kitchen shutters and bathroom cabinets.

Blockboard: Lightweight, strong across long spans like doors and tables.

WPC (Wood-Plastic Composite): 100% water-resistant, excellent for outdoor or utility furniture.

5. Health & Sustainability

Choose E0/E1 grade plywood (low formaldehyde emissions) for healthier air. Eco-friendly, low-VOC boards are increasingly available in India, and worth the small premium — especially for bedrooms and kids’ rooms.

6. Finish Compatibility — Think Ahead

Natural Veneers: Add richness and elegance.

Laminates: Affordable, versatile, and low-maintenance.

Paint/Polish: HDF and MDF are smoother for painted finishes.

👉 Always ensure the base plywood bonds well with your chosen finish.

7. Budget vs Longevity — Spend Where It Matters

Invest in high-quality plywood (BWR/BWP, hardwood-core) for kitchens, wardrobes, and beds. For secondary furniture or decorative panels, commercial ply or MDF can keep budgets balanced.

Key Takeaway

Plywood is more than just a sheet — it’s the silent partner in your home’s longevity. From commercial alternate-core to marine BWP, from flexible curves to fire-retardant safety, each type has its purpose. Choose wisely by matching grade, thickness, and finish to your furniture’s function.

At Design Within, our approach balances Vastu principles with modern practicality. We help you select the right materials — because truly timeless interiors are built on strong foundations.

FAQ's

MR (Moisture-Resistant) is suitable for dry interiors like wardrobes. BWR (Boiling Water-Resistant) can handle kitchen moisture. BWP (Boiling Water-Proof / Marine) is fully waterproof for bathrooms, kitchens, or outdoor use.

Look for the ISI mark, check edges for voids, feel the weight (denser = stronger), test screw-holding on a sample, and perform a small water spot test to check moisture resistance.

Common types include MR, BWR, BWP/Marine, Hardwood plywood, Softwood plywood, Flexible plywood, Fire-Retardant plywood, and Veneer-finished plywood. Each type has specific use cases.

Yes, HDF and HDHMR are engineered alternatives. HDF is denser and smoother for painted surfaces, while HDHMR is moisture-resistant and ideal for kitchens or wet areas.

Use 6–9 mm for back panels, 12 mm for lightweight doors or shelves, 18 mm for standard cabinets and wardrobes, and 25 mm for heavy-duty countertops or tabletops.